The new generation Rotogravure Press is led by ELS technology. By perfectly integration of advanced electronics and ergonomically designed mechanical components to deliver optimum performance, better operational ease, faster print register response, higher productivity, better print quality, less waste, optimising ink solvent and energy consumption, faster job changeover etc.

BrochureGalleryStandard Technical Specification |

|

| Maximum web width | uoto 1300 mm |

| Printing cylinder repeat range | 450 to 920 mm |

| Maximum mechanical speed | 450 m/min |

| Web tension range | 60 to 400 N |

| Standard drying hood length | 2.0 mtr |

| Reel diameter | 1000 mm |

With its cutting-edge features, it delivers print consistency, exceptional productivity, and helping converters with the new trends on achieving high- quality products at high speed sustainably on a wide range of material with utmost ease and unparalleled affordability.

The machine has advance register performance, semi floatation drying with high efficient ventilation module for high-speed drying which ensure minimum residual solvent on the substrate. Fast job changeover with advance ink and cylinder management system, making Pelican Solomark

6450 suitable for today’s market; overall minimal wastage (pre-register setup, shorter web path, quick job setup, minimal ink consumption), and maximum uptime.

FOLLOWING OPERATIONAL CONTROLS ARE AVAILABLE ON EACH STATION...

Fully automatic bi-directional reel splice at machine production speed.

The system mainly composed of push button initiated motorized rotating disc, pneumatically loaded automatic splicing arm, rubber covered pasting roller and cutting blade assembly etc.

Pneumatically expanded self-centering shafts and heavy duty safety chucks to hold the reels.

Unwind Web Handling Control Control using latest generation AC servo technology. The system mainly composed of AC servo motor and drive, pneumatically loaded low friction dancing roller assembly and load cell for tension feed-back and actual tension display.

Electro-electric Edge Guiding System

The system provides precise tension control of the web before entering to the first printing station and isolates the printing unit from tension disturbance of the unwinding zone. Dancing roller on pivoting lever mounting loaded by a counterweight (Unique mechanism for tension feedback) having motorized movement by means of slo-syn motor. The dancing roller position controls the speed of the in-feed motor./p>

All the printing units, Unwinder, Rewinder, in-feed, and out- feed are individually driven by servo motors-drives and controlled and supervised by the high performance motion controller having its own intelligent software.

Advance automation ensuring process repeatability and required productivity.

'Ethernet / IP based communication system' used to maintain tight synchronization between all the drives by providing fast reliable and jitter-free communication.

Master operator control console consists of IPC touch screen operator interface, located at rewind side and remote operator control panel at unwind side, as well as each and every printing units facilitates ease in operation.

Each print unit mainly consists of pneumatic controls for doctor blade group, impression rubber sleeve and electrical controls for manual length and side-lay register settings, temperature controller for drying chamber, hooter and emergency stop etc.

The sleeve system, consists of an air mandrel with a rubber covered fibreglass sleeve.

Raising - lowering on precision sliding guides with low friction precision linear bearing, which ensure smooth and precise displacement.

Automatic detach of the impression sleeve at machine stop by using special pneumatic cylinder having intermediate stoppage facility.

Connection of print cylinder to the motor drive is direct (True direct transmission, without using any reduction ratio components) through a mechanical clamping system ensures fast and easy cylinder locking.

Doctor blade group sliding on low friction ball bushings to eliminate the stick-slip problem. Very sturdy doctor blade group, independently adjustable in height, parallelism and angle. In addition, the group can be tilted backward to allow the replacement of the doctor blade without use of tool.

Designed to ensure a straight profile of the blade resulting in lesser blade pressure, better print quality and longer cylinder life.

Doctor blade supporting assembly with precision adjustment for height and parallelism to the printing cylinder, thus allowing to work in different doctor blade angles; reference position scales, to guarantee repeatability for future productions.

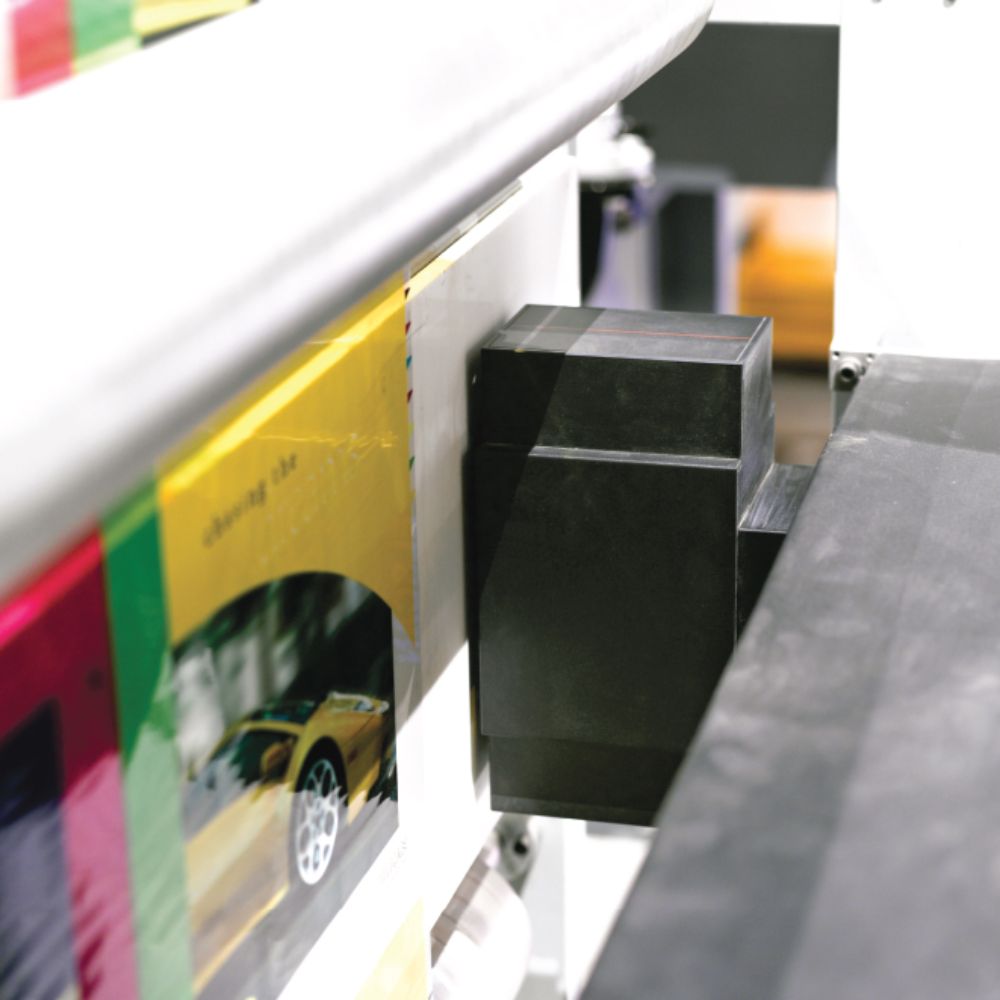

Advance ink and cylinder management system; ink tray and cylinder in print unit has possibility to manage in-out of ink tray and print cylinder, individually and both together for fast job setup and changeover.

Minimum ink volume in circulation.

Flexible solution for increasing productivity and uptime, while decreasing costs.

Perfectly register all print units right from the start at the touch of a button, whether it is a new or repeat job, with minimum start-up waste. Fast and simple operation regardless of the operator skill.

Innovative high efficient drying system. Better heat and mass transfer are achieved by switching from the standard nozzle to arrays of circular impinging jet "3D" holes on the printed side and "2D" holes on the backside, blowing on both sides of the web.

Pneumatically expanded shafts and safety chucks to hold the reels.

Holes shaped and distributed on stainless steel plate to guarantee the maximum energy transfer efficiency and minimize the number of idle rollers in order to avoid shaking or deforming of the web itself.

The system allows full process control for the drying operation to reduce energy consumption and avoids solvent retention in the printed substrates.

Pneumatically operated drying hood opening/closing to allow easy access for web threading and cleaning.

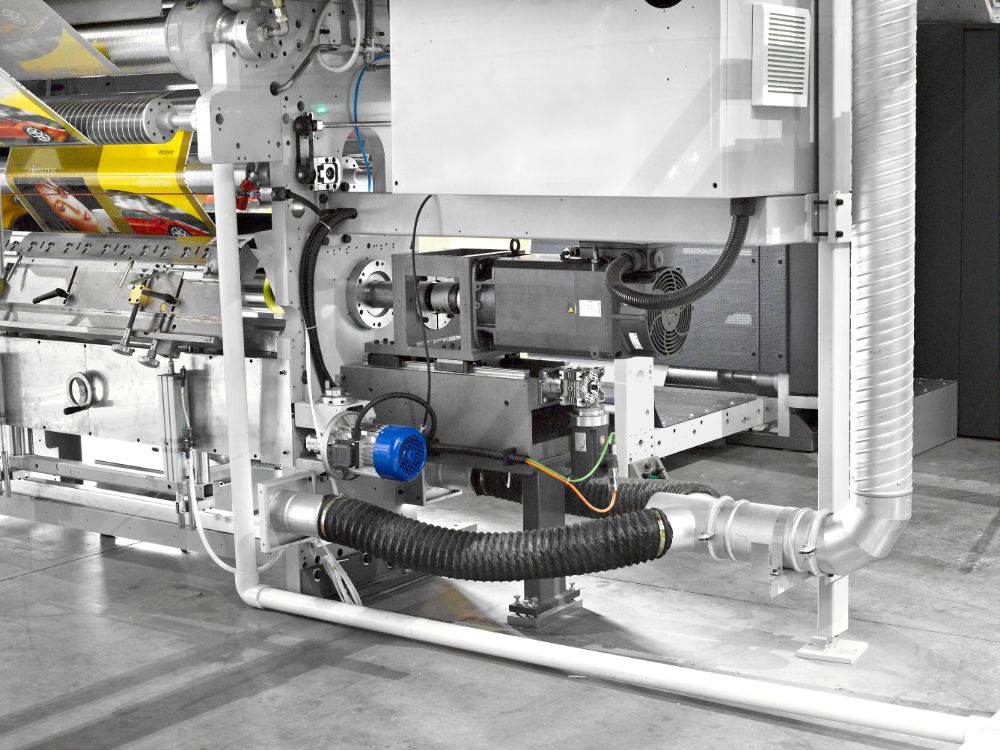

High efficient ventilation module ensuring optimum drying at minimum energy consumption. The system comprising servo controlled damper to set recycling of supplied air to the drying hood and setting of the exhaust air.

EACH VENTILATION MODULE COMPOSED OF :

Thermal oil heat exchanger with necessary controls/feedback devices to maintain set temperature.

Central exhaust system common for all printing units

Separate blower with necessary duct for floor sweep which ensure to reduce solvent contaminated odour within the lower area of the printing stations.

Specially designed, dynamically balanced low friction-low inertia idle rollers made of anti-corrosion Aluminum alloy mounted on low friction bearings, enhance rotational smoothness.

Metallurgy, Shaft end, Internal Boring of the aluminum pipe is done, computerized Dynamically balancing, bearing with self- lubricate, temp resist grease.

The system provide precise tension control of the web before entering to the rewinder and isolates the rewinder from tension disturbance of the printing unit. The system mainly composed of AC servo motor and drive, pneumatically loaded low friction dancing roller assembly and load cell for tension feed-back and actual tension display. The dancing roller position control the speed of the out-feed motor.

Turret type Rewinder with flying splice.

The system mainly composed of push button initiated motorized rotating disc, pneumatically loaded automatic splicing arm, rubber covered pasting roller and cutting blade assembly etc.

Pneumatically expanded self-centering shafts and heavy duty safety chucks to hold the reels.

Rewind Web handling Control using latest generation AC servo technology. The system mainly composed of AC servo motor and drive, pneumatically loaded low friction dancing roller assembly and load cell for tension feed-back and actual tension display.

Web break detection detected by the dancer roller position.

Lay- on Roller Assembly

Pneumatically operated lay on roller assembly complete with

pressure gauge and regulator for control of the pressure on

the rewind reel.

Motorized web video inspection system consists of high quality CCD color camera, Industrial PC & Monitor (facilitates sequential inspection of the lateral and entire print repeat of the web).