The machine is designed to handle a wide range of laminating jobs and to cater growing needs of solvent-less lamination on flexible packaging market.

High productivity, easy operating, optimum energy consumption and ability to handle wide range of laminating jobs are the key features.

By perfectly integration of the new generation of electronics and ergonomically designed mechanical components, the machine is made to deliver optimum performance and productivity.

Standard Technical Specification |

|

| Machine Speed | 400 m/min |

| Maximum Web-Width | 1130 mm & 1330 mm |

| Maximum Laminating Width | 1115 mm & 1315 mm |

| Minimum Film Width | 600 mm |

| Maximum Reel diameter Unwinder & Rewinder | 1000 mm |

| Maximum Reel Weight Unwinder & Rewinder | 800 kgs |

| Core Diameter for Unwinder | 3” (76mm) & 6” (152mm) |

| Core Diameter for Rewinder | 6” (152 mm) |

Created to cover the growing needs of solvent-less lamination on flexible packaging market. Enhanced performance, on one hand, and the easy operating features on the other, are the main reasons to select this machine, joined with its ability to handle a wide range of laminating jobs. The machine has been specially designed, focusing on short and medium runs on solvent-less applications over plastic films.

By perfectly integration of the new generation of electronics and ergonomically designed mechanical components, the machine is made to deliver optimum performance and productivity.

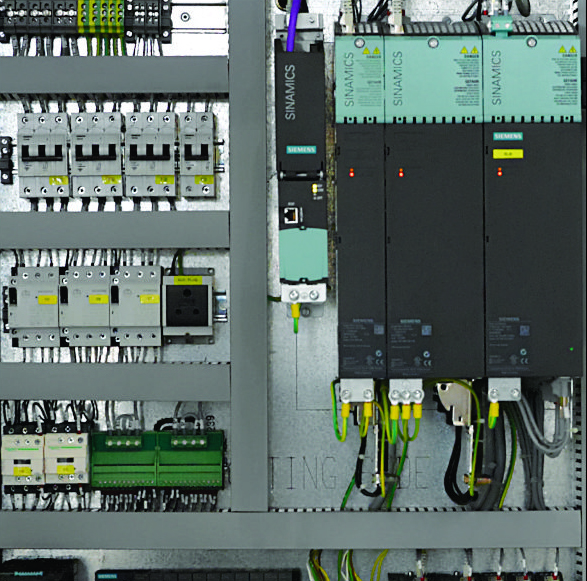

Servo based closed loop controller for web handling by using latest generation of electronics. Entire machine operation is controlled and supervises by high performance motion controller having its own intelligent software.

Master operator control panel consists of touch screen operating interface facilitates ease in operation. Safety of operator, machine and electronic modules are achieved with the help of necessary hardware protection and intelligent software routines.

Distinctively designed and precisely machined, strong and sturdy, steel frame structure, with stiffening tie-rods; maintains accuracy over long dependable life and ensures less vibration even with optimum line speed. The structure enhances illumination of the working area.

The mechanical construction of each component, which undergoes extensive tests, ensures optimum performance and longer equipment life.

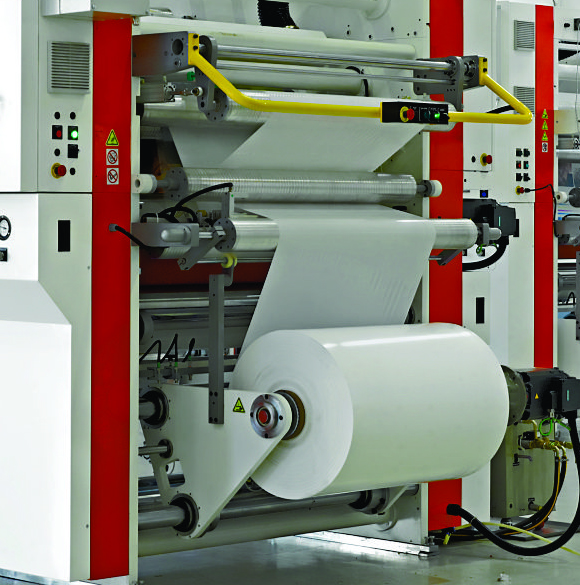

Shaft-less unwind & rewind web tension controlled by using latest generation servo motor and servo drive. The system maintains the set tension precisely throughout the reel run. The system mainly composed of AC servo drive and servo motor, pneumatically loaded low friction dancing roller assembly and load cell for tension feed-back and actual tension display.

The unwind & rewind arms move on high precision linear bushings and supported on ground chromeplated steel bars.

The cylinder includes an innovative floating system which, by means of a touch-screen, allows the operator to set and modify the adhesive quantity easily. The system facilitates cleaning operation easier.

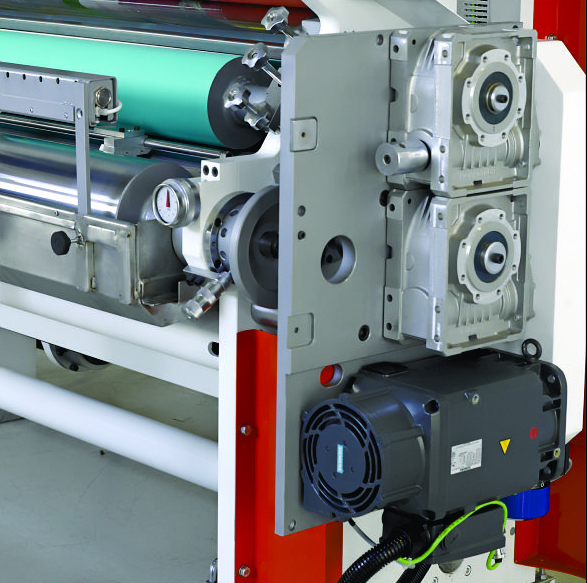

Adhesive applicator zone comprises multi roller transfer system,

(1) R1 roller and

(2) R2 roller are metering Roller.

(3) R3 Transfer Rubber Roller

(4) R4 is Applicator Roller

(5) R5 is rubber covered Pressure Roller,

through the high precision machining and high quality engineering resulted more uniform and accurate coating across the width of the web.

Specially designed, jacketed type, high precision grounded chrome-plated steel rollers, heating through water/oil to a maximum temperature of 80 C. A micro-metric device used to control the gap between the R1 & R2 rollers. This gap allows initial adjustment of adhesive’s amount need to transfer. The gap can be adjusted considering viscosity or type of adhesive used on the machine.

R3 Roll (the Metering Roll) is clad with vulcanized rubber and is rectified at the width of the support to be laminated. R3 Roll handles the metering and transfers adhesive from R2 to R4, the applicator roll.

The R1 Roll, not driven at time of production but can be rotate manually if required.

The R2 & R3 rolls, driven by common AC servo motor & gear box and controlled through a servo drive. The speed of the R2 & R3 is proportionate to machine speed and can be vary to control the amount of adhesive to apply.

R4 Roll transfers adhesive from the roller R3, to the substrate to laminate. It is made of chrome-plated steel, jacketed type ensures uniform heating across the roller face length.

R5 Roll made of steel and covered with hard rubber, presses the R4 roll by means of two pneumatic cylinders, so that it guarantees the total transfer of adhesive to the web.

The laminator unit comprises a heated chromeplated, ground steel roll, a rider roll, coated with hard rubber & chrome plated steel back-up roller which is driven by pneumatic pistons which can be adjusted at both ends. the Steel back-up roller is press against the rubber roller for a total parallelism and to avoid any rubber roller flexion.

The laminator steel roll is driven by an independent motor synchronized with the applicator unit motor by load cells, so the tension on the web carrying the adhesive to the point of lamination can be controlled with great precision.

Specially designed, dynamically balanced low friction-low inertia idle rollers made of Aluminum alloy, mounted on low friction bearings, enhance rotational smoothness.